If you can visualize a crater 20 meters deep and 80 meters in diameter at the surface ,in which a blazing fire sends its flames 9 meters above the top of the crater and 18 meters wide then you can understand something of the problem attached to extinguishing a volcano caught fire in Rumania burning 250.000.000 cubic feet of gas a day . This well owned by a Rumanian subsidiary of Standard Oil Co. of New Jersey in the Moreni field burned from May 22. 1929. until November 4. 1931 . Kinley did not take charge until August 1931 but before Kinley’s experiences at this well are related, it is worth while examining just what causes oil and gas well fires and what are the usual methods of putting them out . Oil well holes are about 20 inches in diameter at the top and taper down to six or eight inches at the boltom . As the hole is drilled casing pipe is inserted and when an oil or gas sand is reached the drilling tools are withdrawn . Gate valves are placed on top of the casing just before drilling into the oil or gas sand, and these valves connect with storage tanks . As a general rule oil or gas does not immediately flow when the sand is struck .The oil sand is like a sponge and from 50 to 150 quarts of nitroglycerin are lowered down the casing to the bottom of the well . This is set off and the explosion breaks up the oil sand that the sand releases the oil much as a water soaked sponge releases water when pressed .The gas pressure which is created pushes the oil to the surface . As the oil comes the valves are adjusted and the well becomes a producer .However, there are times when wells come in prematurely, without the need of explosives and before tools are out of the wells or valves installed . Often tools weighing tons are blown out by the gas, which frequently reaches a pressure of 2500 pounds per square inch . Sometimes these tools create sparks as they are blown out and the gas or oil catches fire . There are other causes, such as lightning, which may strike a well .However, it is seldom known what the exact cause is, for if anyone is sufficiently close to know, the explosion usually kills him .To put the fire out, Kinley usually sets off a of gelatinized nitroglycerin at the mouth . First ,however, the red-hot debris must be cleared away so that the flames will be concentrated into a single upright column . Grappling hooks and huge cables are used to pull away the debris .

If you can visualize a crater 20 meters deep and 80 meters in diameter at the surface ,in which a blazing fire sends its flames 9 meters above the top of the crater and 18 meters wide then you can understand something of the problem attached to extinguishing a volcano caught fire in Rumania burning 250.000.000 cubic feet of gas a day . This well owned by a Rumanian subsidiary of Standard Oil Co. of New Jersey in the Moreni field burned from May 22. 1929. until November 4. 1931 . Kinley did not take charge until August 1931 but before Kinley’s experiences at this well are related, it is worth while examining just what causes oil and gas well fires and what are the usual methods of putting them out . Oil well holes are about 20 inches in diameter at the top and taper down to six or eight inches at the boltom . As the hole is drilled casing pipe is inserted and when an oil or gas sand is reached the drilling tools are withdrawn . Gate valves are placed on top of the casing just before drilling into the oil or gas sand, and these valves connect with storage tanks . As a general rule oil or gas does not immediately flow when the sand is struck .The oil sand is like a sponge and from 50 to 150 quarts of nitroglycerin are lowered down the casing to the bottom of the well . This is set off and the explosion breaks up the oil sand that the sand releases the oil much as a water soaked sponge releases water when pressed .The gas pressure which is created pushes the oil to the surface . As the oil comes the valves are adjusted and the well becomes a producer .However, there are times when wells come in prematurely, without the need of explosives and before tools are out of the wells or valves installed . Often tools weighing tons are blown out by the gas, which frequently reaches a pressure of 2500 pounds per square inch . Sometimes these tools create sparks as they are blown out and the gas or oil catches fire . There are other causes, such as lightning, which may strike a well .However, it is seldom known what the exact cause is, for if anyone is sufficiently close to know, the explosion usually kills him .To put the fire out, Kinley usually sets off a of gelatinized nitroglycerin at the mouth . First ,however, the red-hot debris must be cleared away so that the flames will be concentrated into a single upright column . Grappling hooks and huge cables are used to pull away the debris .

Kinley rushes into the tremendous waves of heat to hook the metal parts . Occasionally bad valves have to be pulled out ‘’by their roots’’ . The whole job sometimes takes days .Then comes the task of carrying ‘’gelatin’’ wrapped in asbestos about the size of a large suitcase to the edge of the flame .‘’I may have had narrow escapes ; one never knows in this business says Kinley ’’ .’’A wind may whip the flames around and then it’s all over’’ . Danger ,ingenuity ,perseverance and the help of the Lord , as the Rumanian newspapers stated, were combined in extinguishing the European blaze . At a depth of 1460 meters a high pressure gas sand was encountered .The string of drill pipe was blown out and it is assumed that the pipe caused a spark as it left the hole ,igniting the gas . The derrick burned like a paper bag in a furnace, and the steel and iron equipment was reduced to a mass of glowing metal . The Rumanian engineers agreed on a series of complicated plans which consumed two years and claimed a number of lives before Kinley took over the job . A 60 meters tunnel was dug ,tapping the well about 20 meters below the surface . The object was to lay a pipe in the tunnel and divert the flow of gas, thus shutting off the flow of gas at the well opening and automatically extinguishing the blaze. Unfortunately, the tunnel became filled with gas an explosion followed and four men in the tunnel were killed . Porous ground of a sandy character prevented a second and deeper tunnel from being completed. A third tunnel 240 meters in length which reached the well 80 meters below the ground, was dug and a second explosion killed four more men . This tunnel was cleaned out and in drilling into the casing a third explosion took the life of a ninth man and injured several others . Following the third explosion the well began to crater . The heat from the flames burned the sand about the well mouth to a fine dust which the gas carried into the air to be blown away .This, together with erosion by rains and snow, created a deep hollow in the ground . Some gas was diverted through the soft ground and escaped along the walls of the crater. Ignited by the main fire, numerous ground fires were formed . So when Kinley arrived on August 1. 1931. he found a seething furnace . By the 10th of the month he had demonstrated that explosives would put out the fire by snuffing out the flame for four and a half minutes . Hot materials and ground fires in the crater ignited the gas again . ‘’ I decided ‘’says Kinley ’’ that we must get the gas away from the bottom of the crater with the terrific heat it was difficult to drag out the hot metal and put out the ground fires . So we installed a 9 meters sheet metal stack with a funnel base over the top of the well and this removed the main flame from the bottom of the crater ,allowing us to cool off the metal and put out the ground fires .

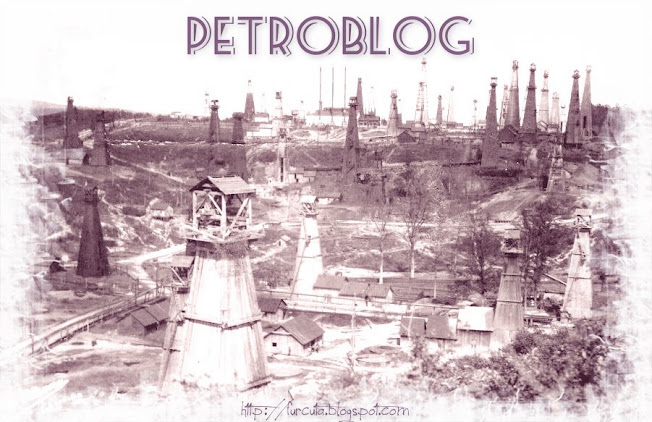

A view of Moreni oilfield and 160 fire. Photo taken from Bana hill.

This done, on August 24 and 25 we set off two shots of ‘’gelatin’’but both missed and the stack fell when guy wires were blown loose . The flame was again at the bottom of the crater . I knew the flame would require a heavy charge of ‘’gelatin ‘’so we next directed our attention to the first tunnel in which the 10 inch pipe was still in place. This was cleaned out and a suction fan placed at the end drew some of the gas from the main flow ,reducing the flame at the crater bottom about 50 per cent . But the metal at the bottom of the crater was again glowing with heat, so in order to cool this and the ground, streams of water were turned into the pit . Finally the softened walls slid over the well mouth and plugged the opening . This was on September 18 . Most of the gas was diverted to the 10 inch pipe, but some broke through the soft ground around the crater . The fire was out( temporarily as it proved),it is true, but this was but our work ,for the well had to be put under control. It was feared that the gas would settle and accumulate in the valley surrounding the property and present a very dangerous fire hazard . Thus mud and water in the crater were removed by a steam injector . This mud boiled like lava as the gas bubbled up through it .It was still hot as the ground had not had time to cool . The mud removed, the gas again caught fire 10 days later ;was shot out but caught again . Things looked discouraging . I charged the banks of the crater and the slide following the explosion smothered the fire on November 4 . This was the last fire in the crater . But we had not yet put the well under control ,and we had no assurance that the gas would not again catch fire . Sparks from the iron debris, caused by dragging the metal from the pit, often set the gas again . We would clean out the crater and snow cavings would refill it. Finally ,however, we succeeded and placed a second stack over the mouth of the well . Cement 10 feet deep was poured around the stack and earth to a depth of 25 feet packed on top of that ,clear to the depth of the first tunnel . Then, at last ,we were able to divert all the gas out of the first tunnel . Thus the well had been conquered as the flow of the gas was connected with a gasoline plant.’’